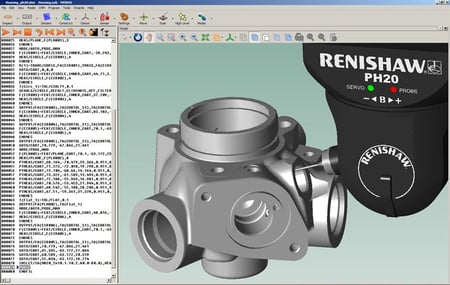

MODUS™ software from Renishaw

MODUS is the powerful platform that fully supports the Revolution® line of CMM’s and 5-axis measurement. A configurable user interface allows native DMIS programs to be developed offline, the drawing of geometry, embedded dimensions and tolerance data from CAD, feature construction and part alignment. MODUS is the only software that can provide full support for all the Renishaw REVO sensors. Advances in sensors, metrology software and controller technology now offer the opportunity to transform existing CMMs, providing greater accuracy, faster measurement, more automation and new capabilities, whilst taking full advantage of CAD-driven programming.

Click here for more specifics on MODUS software

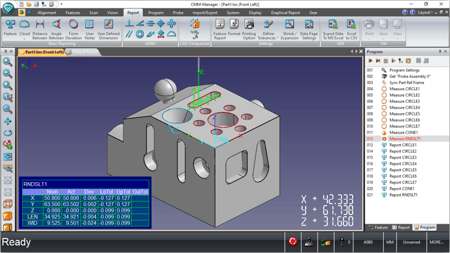

CMM-Manager™ software from QX-Soft

CMM-Manager™ software from QX-Soft

CMM-Manager’s object-based interface allows CMM program creation without complex a text based programming language. CMM-Manager includes flexible functionalities, including graphical probe configuration management, automatic tip calibration, cross section scanning and group feature measurement. Simplify your metrology tasks using our intuitive yet powerful software.

Click here for more specifics on CMM-Manager software

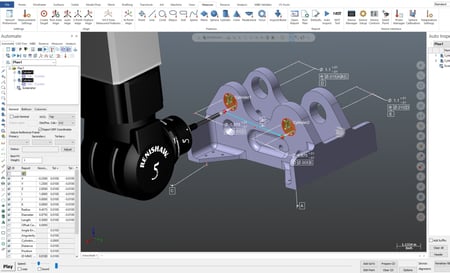

Verisurf Programming & Inspection Suite

Verisurf software is a 3D measurement platform for manufacturing inspection, guided assembly and reverse engineering. The CMM Programming & Inspection suite features an easy-to-use, intuitive graphical interface: simply point and click on the model features to include in the inspection plan. All parameters of probe motion can be controlled, and inspection steps can be grouped easily by drag-and-drop programming.

Click here for more specifics on Verisurf software packages

QC-CALC Software Options from Prolink

QC-CALC Software – is used to collect and display measurement results from all CMMs, Video CMMs, and hand gauges without operator intervention. You can create reports and export data to spreadsheets, databases, and other SPC programs. This means you can transfer data from all of your measurement devices to any SPC package using one program. This is the first program to provide one interface for all machines and one interface for all outputs. The goal is to make your data collection seamless no matter what equipment you’ve purchased or software you use. The seamless integration with automated gauges is the cornerstone of QC-CALC Real-Time.

Click here for more specifics on QC-CALC software packages

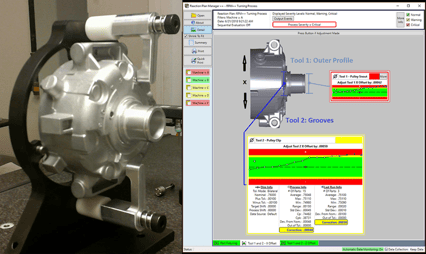

Reaction Plan Manager

The Reaction Plan Manager (RPM) provides productivity tools to reduce complex measurement information into step-by-step machine adjustments. Deciding how to react to a broken or shifted process is critical. Part size and statistical reports may indicate the process has drifted but knowing what adjustments are required is difficult. By using RPM, you combine measurement data with engineering knowledge to analyze the process in real-time and provide specific instructions to fix the process.

Click here for more specifics on Reaction Plan Manager software