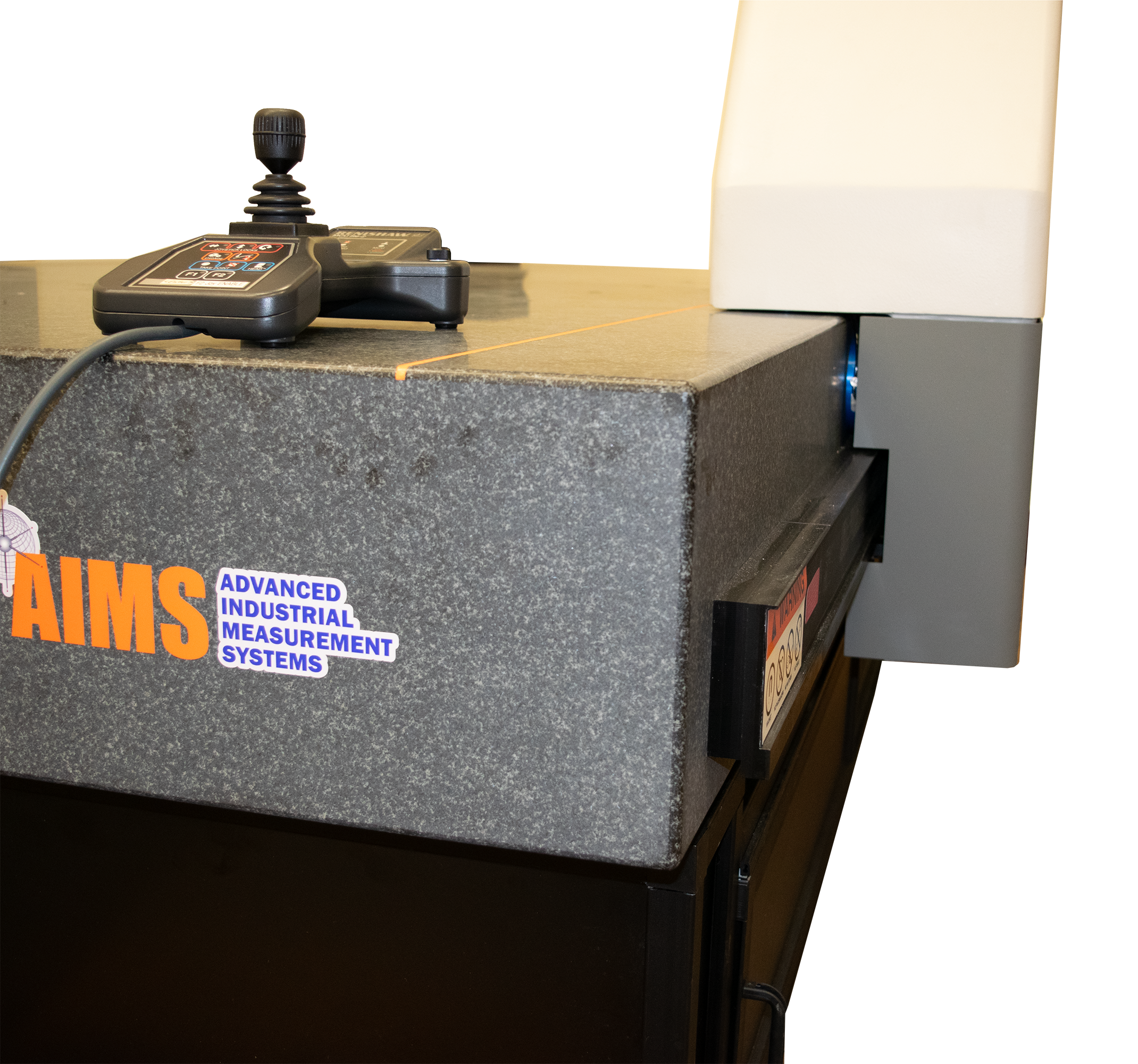

Revolution® Linear Motor CMM

Reliable Linear Motor Driven CMM with 5-axis Capabilities

Click here to read more about this CMM in CMM Quarterly.

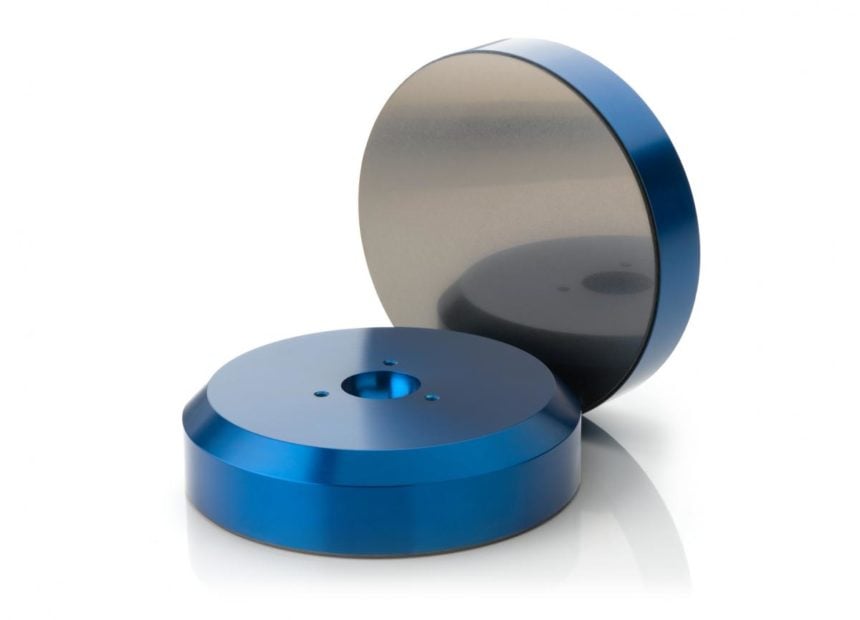

Superior Air Bearings

Our Revolution® LM series uses porous media air bearings to provide superior lift versus conventional single circuit air bearings. These bearings allow the CMM to move faster and position more accurately. These bearings are used on the most accurate positioning systems in the world.

Renishaw Controls

Our Revolution® LM series machines are controlled by Renishaw’s latest digital technologies. From their industry leading scales to their UCC family of CMM controllers. These controllers are specifically designed for CMMs, and all the probes and sensors Renishaw has to offer. These are also open architecture so you as a customer are not locked into service from only the OEM over the life of the machine.

Renishaw REVO 5-axis Probe System

The LM Series CMM’s were designed for Renishaw’s 5-axis technologies from the ground up. Renishaw’s REVO multisensor probe system can run at its full potential with the construction and unique linear motor dives found on the LM series. REVO has the ability for scanning, surface finish, vision, structured light, and ultrasonic thickness measurement.

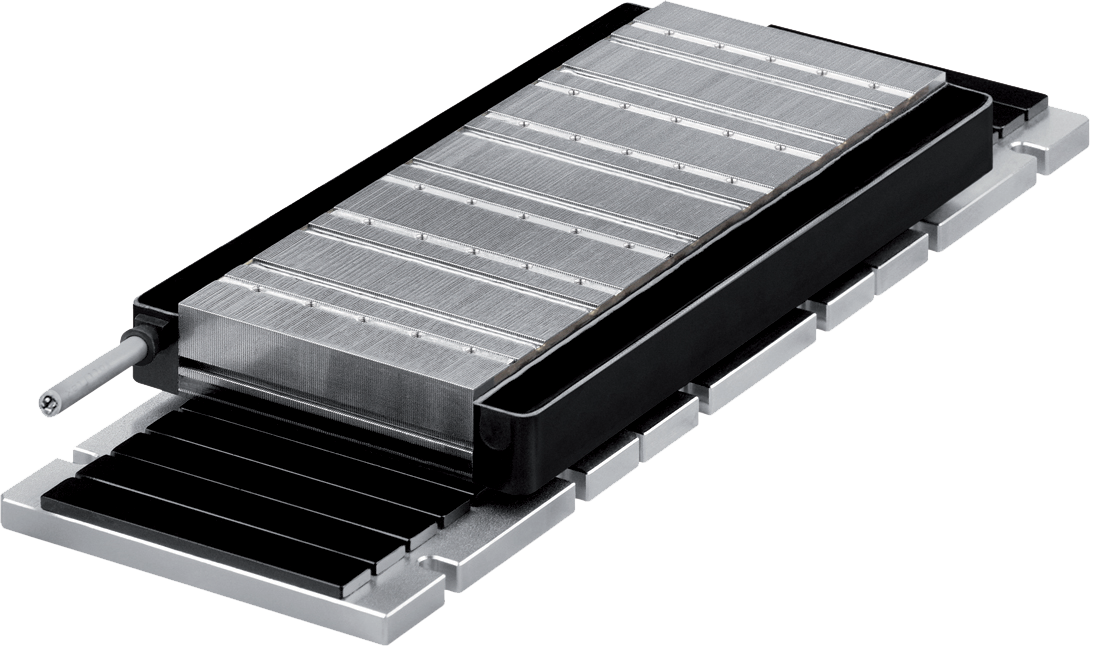

Linear Motor Drives

AIMS Revolution® LM series machines are driven by linear motors. These provide extremely precision positioning, whisper quiet operation, and due to no moving parts, completely smooth motion which is ideal for scanning. This design does not have wear items, so these systems require almost no maintenance for the life of the CMM.

Components

The Revolution® LM can be equipped with Renishaw’s touch or scanning probes and are suitable for all applicable manufacturing measuring applications. This includes Renishaw’s 5-axis PH20, and the REVO-2 which provides triple the productivity of conventional touch/scanning probes, respectively. The linear motor drives provide not only the speed and precision for inspection, but have no moving parts. Both the Renishaw technologies and the linear motors help to give our customers a much lower cost of ownership that other systems.Inspection Software

AIMS has multiple software options to align to your needs. Modus software from Renishaw is built around the 5-axis probe systems. The standard includes Native DMIS, CAD, Modus Organizer, and Graphical Reports. Options include Modus Gear, Modus Spline, Modus Airfoil, and MMclient. MMclient allows sharing between Modus and MeasureMax.

CMM-Manager from QxSoft is the industry's most intuitive CMM Software on the market. This easy to use graphical software provides full collision avoidance programming and automatic path generation for 5-axis probing.

Process Control Software

AIMS Metrology

tel: 937-320-4930

fax: 937-320-4933

ddelph@aimsmetrology.com